Smart Manufacturing

- Home

- Solutions

- Smart Manufacturing

Transforming Modern Manufacturing with ACTECK

Traditionally, manufacturing has prioritized increasing productivity and reducing labor costs. However, the focus of modern manufacturing has shifted towards achieving operational efficiency, ensuring high-quality outputs, and delivering real-time production insights to both operators and management. With the rapid rise of industrial automation, many factories have begun adopting prototypes of smart manufacturing. Yet, digitalization is just the starting point—true smart manufacturing demands centralized management, intelligent monitoring, and advanced algorithms to process raw data from multiple terminals, enabling actionable insights that optimize overall production performance.

ACTECK leverages extensive expertise in smart manufacturing applications to drive this transformation. We offer technical consultation and innovative solutions for manufacturing developers, accelerating the adoption of Industry 4.0 and seamlessly integrating IoT and AI into modern production systems.

Key Features of ACTECK Smart Manufacturing Solutions

ACTECK delivers industrial automation solutions across various industries, including CNC machinery, textile equipment, inspection systems, and factory optimization. We collaborate closely with customers on-site to evaluate challenges, monitor real-time production status, and develop customized solutions that meet specific industry needs and exceed expectations. Key features of our solutions include:

Customization

Every customer has unique requirements. Whether addressing small space constraints, compliance with specific regulations, or specialized input voltage needs, ACTECK tailors solutions to meet exact specifications.

Diversity Device Control

ACTECK’s smart manufacturing solutions are compatible with a wide array of devices, utilizing versatile interfaces such as POE, CAN bus, and COM ports. We also work with customers to reserve expansion slots, ensuring flexibility for future system upgrades.

IP65

Industrial environments demand robust systems. Many ACTECK solutions incorporate waterproof and dustproof features with IP65 compliance, along with PCB conformal coating where required, to meet demanding environmental conditions.

Anti Shock & Vibration

Durability is crucial in industrial settings prone to vibrations. ACTECK designs solutions with anti-shock and vibration-resistant components, ensuring reliability across connectors, cables, memory, storage, and entire systems.

Wide Temp Range

ACTECK systems are designed to operate reliably across a wide temperature range, from -40°C to 70°C, ensuring stability in even the harshest industrial environments.

Fan-Less System

For use in harsh or windless environments, ACTECK incorporates fan-less designs into its systems, ensuring consistent performance without compromising reliability or efficiency.

Success Stories with ACTECK

CNC Machinery

Factory Test Tool Add-On Cards

Automatic Yarn Winding Machine

Automatic Optical Inspection (AOI)

Successful Stories

CNC

Factory Test Tool Add-on Card Factory

Textile Industry Automatic Yarn Winding Machine

Automatic Optical Inspection

Our Products

EBC-01004

- Fanless and rugged design

- On board Intel®Whiskeylake I7 8565U Processor.

- 2*DDR4 SODIMM Memory, support 2133MHz ram, max up to 32GB

- Support 1*HDMI, 1* VGA display out

- 2* WGI211AT Gigabit Ethernet, support Wake on Lan, PXE

- 6* DB9 RS232 COM port COM3~COM6 support RS232/RS485

- 1*12PIN Phoenix connector, 4-in 4-out GPIO,switch、5V

- DC 9~36V wide voltage input

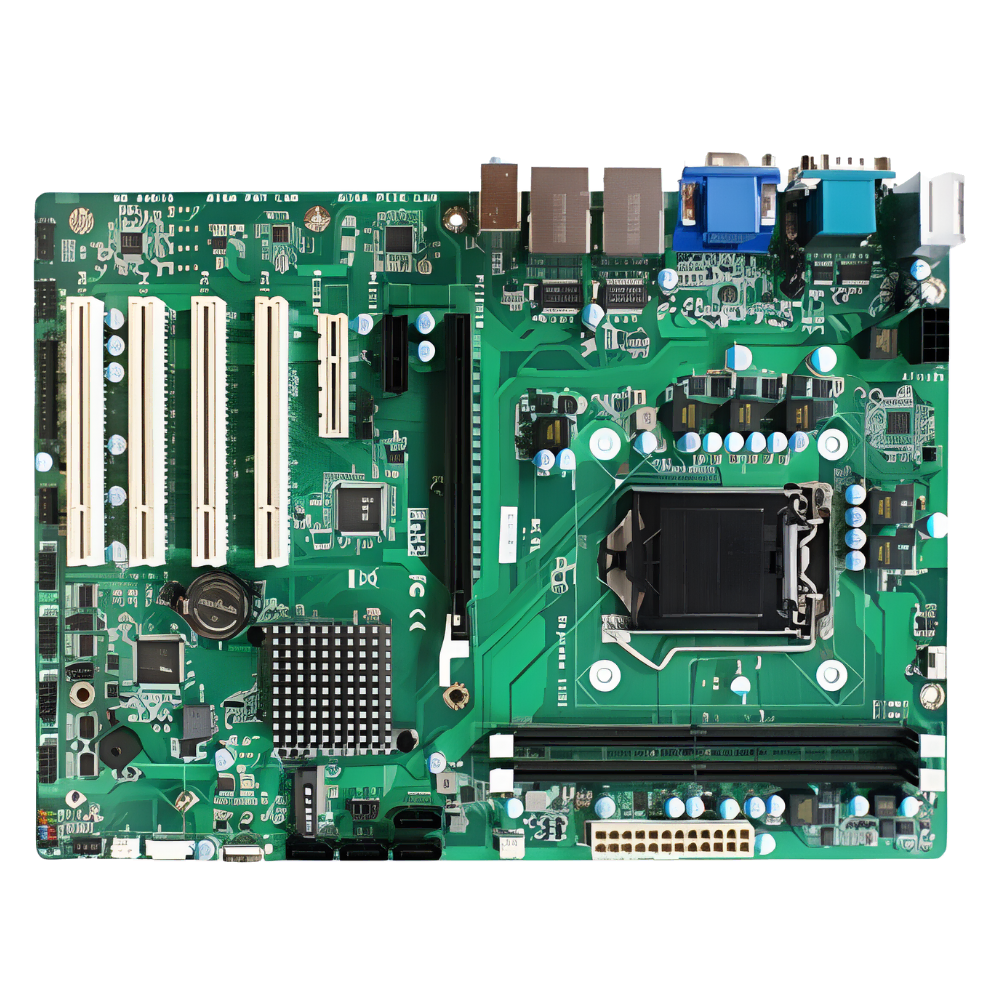

ATX-05003

- Intel® LGA1151 Socket Core i3, i5, i7 Pentium Processor

- 2* DDR4 2133MHz long-DIMM up to 64 GB

- 1* Intel® I219LM GbE, 1* Intel® i211AT GbE

- Support HDMI&VGA

- 2* External COM, 4* Internal COM (COM1 support RS232/422/485, COM1/2/3/4 support 5V/12V TTL)

- 4* USB3.0, 5* USB2.0 (internal USB2 Support Dongle)

- Support TPM 2.0(Optional)

NAR-16002

- 2U Rackmount based server.

- Intel 12/13/14th Gen Processor.

- 1* VGA Resolution1280 x 1024

- 1*PCIe4.0 x 16, 1*PCIe3.0 x4, 2 x 32bit PCI

- 6 x USB 3.0, 6 x USB 2.0

- 6 x serial port

PPC-02004

- 10.1″ true color LCD display with 1280*800 resolution

- The front panel is IP65 rated to prevent dust and splashing water droplets from entering the display.

- Intel Celeron Processor.

- 12V DC power input.

- High-precision capacitive screen

- Both panel embedded and standard VESA mounting are supported.

- 2x USB, 2 x GLAN