Quality Management

- Home

- About Us

- Quality Management

Acteck Manufacturing Excellence

At Acteck, we are committed to setting the standard for manufacturing excellence. By combining advanced technologies, innovative processes, and a focus on quality, we provide industry-leading manufacturing solutions tailored to meet the diverse needs of our clients.

Core Manufacturing Capabilities

Automated Component Inventory Management: We utilize advanced automation to ensure precise and efficient inventory control, reducing downtime and optimizing productivity.

SMT Lines: Equipped with state-of-the-art Surface Mount Technology (SMT) lines, we ensure precision and reliability in PCB assembly processes.

Comprehensive PCB Testing: Every circuit board undergoes rigorous functional testing to guarantee durability and top performance.

System Integration: Seamless integration processes ensure that all components work together perfectly to meet customer specifications.

Flexible Production Capabilities: Whether it’s a small batch or large-scale production, our adaptable manufacturing systems cater to the unique requirements of every project.

Empowering People Through Comprehensive Training

At Acteck, we understand that exceptional manufacturing starts with skilled and knowledgeable employees. That’s why our Manufacturing Operation Center places a strong emphasis on continuous training and development.

Employee Training Program Highlights

- Pre-Employment Training: Ensures every new team member is equipped with the foundational knowledge and skills needed for their role.

- On-the-Job Training: Hands-on learning tailored to specific job requirements ensures practical expertise.

- Regular Training: Ongoing development sessions ensure employees stay updated with the latest processes, technologies, and standards.

- Regular Assessment: Frequent evaluations identify areas for improvement and ensure consistency in performance.

We reassess individual training needs whenever new equipment, products, or processes are introduced. By focusing on competency and quality trends, we ensure our team delivers stable, reliable, and superior-quality results. Retraining is provided whenever necessary to address any gaps, ensuring excellence at every level of the production process.

Commitment to Quality Control

Quality Control

- Material Inspection: All incoming materials are thoroughly inspected. Rejected items are returned to suppliers with detailed feedback for corrective action.

- In-Process Quality Checks: Quality inspections are conducted at every stage of production to maintain consistency and address issues immediately.

- Final Product Inspection: Before delivery, every product undergoes rigorous final checks to ensure it meets customer expectations.

- Documented Procedures: Comprehensive documentation accompanies each step of the process, ensuring traceability and adherence to protocols.

- Equipment Calibration: All equipment is regularly calibrated and maintained. If discrepancies are identified, the last three product lots are re-tested with calibrated tools.

We also integrate Manufacturing Execution System (MES) software to ensure that each assembly station completes all required steps before moving forward, minimizing errors and optimizing efficiency.

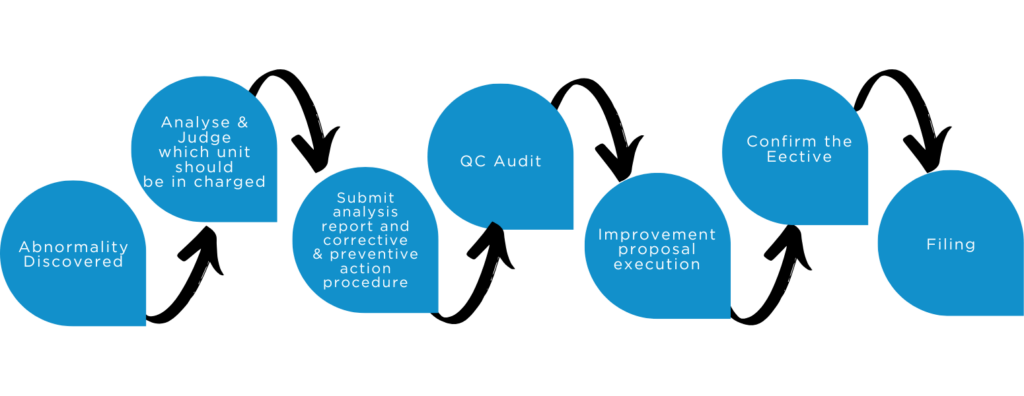

Corrective and Preventive Action (CAPA)

At Acteck, we don’t just resolve problems—we prevent them. Our Corrective and Preventive Action (CAPA) program is designed to address abnormalities proactively, ensuring they don’t impact our clients or reoccur in the future

CAPA in Action

- Proactive Monitoring: Our QA team continuously monitors production for irregularities and identifies potential issues early.

- Supplier Collaboration: When issues arise, we work closely with suppliers to investigate root causes and implement effective solutions.

- Root Cause Analysis: Every issue is analyzed in detail, and corrective actions are documented for reference and improvement.

- Supplier Corrective Action Form (SCAF): Issues are formally documented, and resolutions require approval from both Acteck and the supplier. These records are maintained in our Quality Management System (QMS) for accountability.

- Monthly Case Reviews: Open cases are reviewed on a monthly basis to ensure timely resolution and continuous improvement.

By addressing problems at their source and implementing measures to prevent recurrence, Acteck ensures consistent quality and reliability for every product we deliver.

Why Choose Acteck?

Acteck is not just a manufacturer—we are your partner in success. With a strong foundation built on innovation, quality, and customer satisfaction, we offer unmatched manufacturing excellence that supports your business growth.

Key Benefits of Working with Acteck:

- Advanced Technology: Cutting-edge equipment and automation drive efficiency and precision.

- Skilled Workforce: A well-trained team ensures consistent quality and reliability at every stage of production.

- Robust Quality Systems: Comprehensive quality control processes ensure that every product meets or exceeds expectations.

- Proactive Problem Solving: Our CAPA system prevents issues before they arise, providing peace of mind to our clients.

At Acteck, we believe in building lasting relationships with our clients. By focusing on quality, efficiency, and continuous improvement, we empower businesses to achieve their goals and stay ahead in today’s competitive marketplace.